What is a Digital Twin?

A digital twin is the digital version of a real-world product, service, or process. The digital twins act as a link between the real world and the digital world. They do this by using sensors to get real-time information about an object. This information can be used to make digital copies of an item, which can then be understood, analyzed, changed, and improved.

The collected data helps businesses do better analysis, predict problems ahead of time, or even send out early warnings. Using simulations also helps businesses find new business opportunities and plan better products for the future at lower costs. These results of digital twins would help businesses give their customers a better experience.

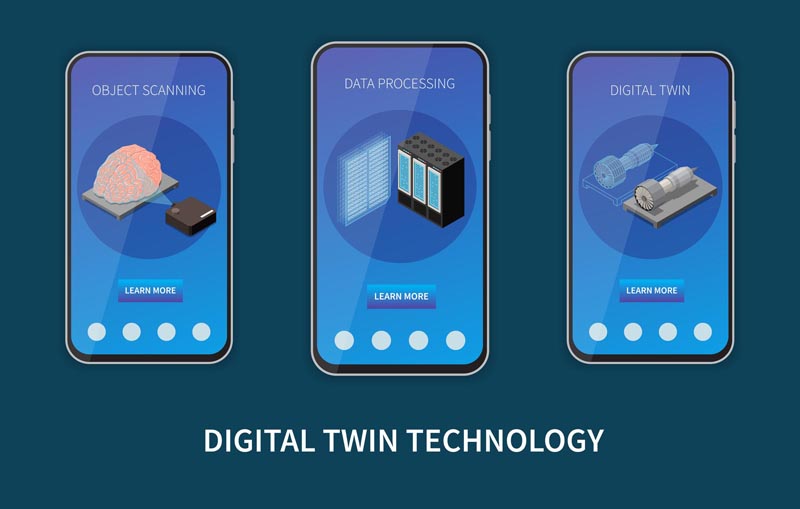

Digital twin technology is based on three fundamental ideas. The first is that there is a physical object or device in the real world. The second is that there is a virtual product in the digital world. Finally, there is a bridge between the physical and virtual objects that helps send and receive data and information.

How Digital Twin Works

Smart parts are built into physical objects or systems. These smart parts are used to collect data in real-time. Most of these parts are linked to cloud-based systems that track the data they collect and use the final data to make things.

To make a digital twin of any physical object, data from different sources, such as physical data, manufacturing data, operational data, and analytics software insights, are collected and put together. The collected data is then put into a physics-based virtual model, and when analytics are used on these models, useful information about the object can be learned.

This steady flow of data makes it possible to get the best possible analysis and insights about an object, which can then be used to improve business results. So, the digital twin will be a live version of a real object.

Types of Digital Twins

Product Digital Twins

Digital Twin is a product that connects the virtual world to the real world. It can be utilized to look at how a product works in different situations and make changes in the virtual world to ensure the real product works exactly as planned.

Digital twins of products help people figure out how to deal with the complexity of systems so they can create the best decisions possible. There is no need for multiple prototypes, which reduces total development time and improves the product. Digital Twins also make it possible to quickly make changes in response to customer feedback.

Production Digital Twins

Before going into production, a manufacturing process can be tested on the floor with the help of a “production twin.” By simulating a process with the Digital Twin and then using the digital thread to figure out why certain things happen, companies can make a more efficient way to make things under a set of conditions.

The production process can be improved by making digital copies of all the equipment used in production. Using data from digital twins of products and production, businesses can keep their equipment from breaking down and know when preventive maintenance is needed. A steady flow of accurate information ensures that manufacturing operations are quick, reliable, and efficient.

Performance Digital Twins

Smart products and plants make a lot of information about how they are used and how well they work. The performance Digital Twin can collect this data from products and plants in use and then analyze it to give insights that can be used to make better decisions.

Companies can, by utilizing the performance Digital Twin,

- Find new ways to do business.

- Find out how to make the virtual models better.

- Get the operational data, put it all together, and look at it.

- Make the products and production system work better.

Uses of Digital Twins

The idea of a “Digital Twin” is almost the next big thing for many businesses. By looking at the digital versions of real-world objects, you can accurately predict their current and future state.

When organizations use Digital Twins, they tend to learn more about how their products work, how to improve their customer service, and how to create better operational and strategic decisions based on what they learn.

Some of the most important ways that Digital Twins could be used in business are,

Manufacturing

Digital Twins can greatly affect how products are designed, made, and kept in good condition. It has made production more efficient and optimized while reducing the time required to get things done.

Automobile

With the help of digital twins, virtual models of connected vehicles can be made. It records how the vehicle works and how it behaves. This helps analyze the overall performance of the vehicle and its connected parts. It may also help make sure that customers get a service that is truly tailored to them.

Retail

Digital Twins is a key part of improving the customer experience in retail. This can be done by giving customers virtual twins and letting them try on clothes on them. The Digital Twins could also help with better store planning, better security measures, and managing energy in the best way possible.

Healthcare

Digital Twins and the Internet of Things are important in the healthcare industry. They can help save money, keep an eye on patients, do preventive maintenance, and even provide personalized health care.

Smart Cities

Planning a smart city and putting it into action with Digital Twins and IoT data can help boost economic growth, make better use of resources, and improve the overall quality of a citizen’s life. Using the various sensor networks and smart systems, the Digital Twin model can assist city planners and people who make policies for smart city planning.

Industrial IoT

Industrial companies that use digital twins can now digitally track, monitor, and control industrial systems. In addition to operational data, digital twins can also record data about the environment, such as location, configuration, etc., which helps predict how operations will go in the future.

Digital Twins in the Future

In 2017, the global Digital Twins market was worth $2.26 billion, and it is expected to increase at a compound annual growth rate of 38.2% from 2018 to 2025. The main things driving this industry’s growth are the growing use of IoT and IIoT and the rapid rise of digitization in industries like manufacturing, automotive, and healthcare.

The growing use of the Internet of Things, powered by 3D simulation, deep learning, machine learning, and big data analytics, will help aerospace and defense, healthcare, retail, and consumer goods implement digital twins cost-effectively.

Also, as this market grows, there is a growing need to cut down on asset downtime, speed up processes, and enhance operational efficiency. During the next few years, this market will be driven mainly by government programs that help build smart cities and buildings that use less energy.